In today’s fast-paced technological world, heavy equipment and machinery, such as excavators, bulldozers, and other construction vehicles, rely on efficient battery systems to ensure they operate smoothly. For those who own or operate machinery models like the X650, X655, X690, X653, X656, X682, X683, X693, BD2, KC8, KG8, KG7, CD6, CD7, or KB8, understanding when and how to replace the 49FT battery is crucial to maintaining performance.

This guide will walk you through everything you need to know about replacing the 49FT battery in these models, including how to recognize the signs of a failing battery, what to consider when selecting a replacement, and how to ensure proper installation and maintenance for optimal performance.

Why Battery Maintenance is Important

Batteries serve as the heartbeat of construction machinery, powering essential functions such as the engine’s start-up, electronics, and hydraulic systems. Without a reliable battery, the functionality of your equipment can be compromised, resulting in unanticipated downtime, increased operational costs, and potential damage to other systems.

The 49FT battery is typically found in various models of construction equipment, and ensuring it is in top condition is paramount to the longevity and efficiency of your machine. Replacing a battery that is not holding charge or showing signs of wear can prevent issues that could negatively affect the productivity of your operations.

Signs That Your 49FT Battery Needs Replacement

The first step in battery maintenance is knowing when it’s time to replace the 49FT battery. Here are common signs that your battery may be nearing the end of its life:

- Difficulty Starting the Engine

If the engine is sluggish to start, or it takes multiple attempts to turn over, your battery may no longer be providing enough power to the starter motor. - Warning Lights

Many modern construction machines are equipped with onboard diagnostic systems that alert operators to low battery voltage or other battery-related issues. If you see a battery light on your control panel, it’s time to check the battery. - Frequent Jump Starts

If you find yourself needing to jump-start your equipment frequently, the battery might not be holding a charge and needs replacing. - Corrosion on Battery Terminals

Excessive corrosion on the battery terminals can indicate that the battery is losing its ability to hold a charge or may be leaking internally. - Diminished Battery Life

A noticeable decrease in the amount of time the machine can run without being recharged is another sign the battery may no longer be reliable.

Choosing the Right Replacement 49FT Battery

Selecting the right replacement battery is crucial to ensure optimal performance and longevity. Here are a few key factors to consider when purchasing a new 49FT battery:

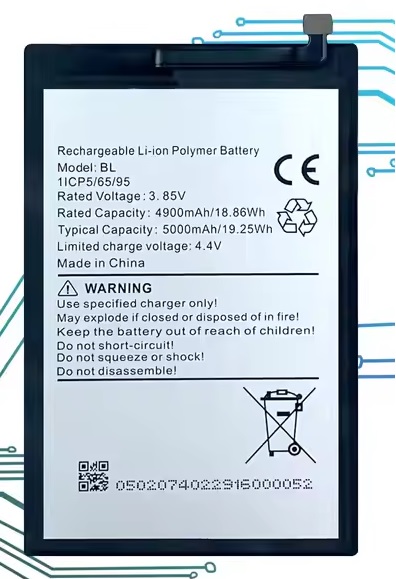

- Battery Specifications

Make sure the replacement battery meets or exceeds the manufacturer’s specifications for voltage, amp-hour capacity, and dimensions. Using an incompatible battery may lead to poor performance and even cause damage to your equipment’s electrical systems. - Brand and Quality

It’s always a good idea to choose a reputable brand known for high-quality, durable batteries. Some popular battery brands for construction equipment include Interstate, Exide, and Odyssey. Check for warranties and reviews from other users. - Cold Cranking Amps (CCA)

CCA is a critical specification that determines the battery’s ability to start the machine in cold conditions. Make sure the CCA rating matches or exceeds the requirements of your equipment. - Battery Type

There are two primary battery types for machinery: Lead-Acid and AGM (Absorbent Glass Mat). AGM batteries are more expensive but generally offer better performance, especially in extreme temperatures. Lead-Acid batteries, on the other hand, are typically less expensive but may require more maintenance. - Maintenance-Free vs. Regular Batteries

Maintenance-free batteries are sealed and do not require regular watering or checking, making them a more convenient choice. However, regular batteries are often more affordable and can be maintained over time if necessary.

Step-by-Step Guide to Replacing the 49FT Battery

Replacing the 49FT battery on models such as the X650, X655, X690, and others can be done efficiently with the right tools and approach. Here’s a step-by-step guide:

Step 1: Safety First

Before you start working on the battery, make sure you’re wearing proper safety gear, including gloves and eye protection. Disconnect the negative terminal of the battery first to prevent any electrical shock or short circuits during the replacement process.

Step 2: Locate the Battery

The 49FT battery is typically housed within a compartment in the rear or side of the machine, depending on the model. Consult your machine’s owner’s manual for the exact location.

Step 3: Disconnect the Old Battery

Using the appropriate tools (usually a wrench or socket set), first disconnect the negative (black) cable, followed by the positive (red) cable. This ensures that there is no electrical flow while you remove the battery.

Step 4: Remove the Old Battery

Once the cables are disconnected, remove any brackets or fasteners that are securing the battery in place. Carefully lift the old battery out of the compartment.

Step 5: Install the New Battery

Place the new 49FT battery into the compartment, ensuring it fits snugly and aligns with any securing brackets. Reattach the brackets or fasteners to keep the battery in place.

Step 6: Reconnect the Battery Cables

Reconnect the positive (red) cable first, followed by the negative (black) cable. Ensure that both cables are tightly secured to the battery terminals.

Step 7: Test the New Battery

Turn on the equipment to ensure that the engine starts easily and that all electrical systems are functioning properly. If you notice any issues, double-check the connections and ensure that the battery is the correct type for your machine.

Proper Battery Maintenance for Longevity

To maximize the life of your new 49FT battery and avoid frequent replacements, follow these maintenance tips:

- Keep Terminals Clean

Corrosion on the battery terminals can impede the battery’s performance. Regularly inspect and clean the terminals with a mixture of baking soda and water to remove any buildup. - Check Battery Voltage

Use a multimeter to check the battery’s voltage regularly. A healthy battery should read around 12.6 to 12.8 volts when fully charged. If the voltage drops below 12.4 volts, it may indicate the battery is not fully charged or is losing its capacity. - Inspect Battery for Leaks or Damage

Regularly inspect the battery casing for any signs of damage or leaks. Leaking batteries should be replaced immediately to avoid further damage to the equipment. - Ensure Proper Charging

Use a battery charger that matches the specifications of your equipment to ensure the battery is charged correctly. Overcharging or undercharging can reduce battery life. - Regular Use

If the machinery is not used regularly, consider starting the engine and running it for a short time every few weeks to prevent the battery from losing charge.

Conclusion

Replacing the 49FT battery in your construction machinery, whether it’s an X650, X655, X690, X653, X656, X682, X683, X693, BD2, KC8, KG8, KG7, CD6, CD7, or KB8, is an essential part of maintenance that can significantly impact performance and uptime. By recognizing the signs of a failing battery, choosing the right replacement, and following proper installation and maintenance procedures, you can ensure that your equipment continues to perform at its best, reducing downtime and repair costs. Regular maintenance will not only keep your machines running efficiently but will also extend the lifespan of the battery and overall equipment.

Stay proactive with your equipment’s battery care, and you’ll see improved performance and longevity, leading to fewer operational interruptions and increased productivity on the job.